How will quality of the paved road be ensured in a fast track attempt?

01 Jun 2022 15:16:08

Implementation of Quality Control and Quality Assurance (QC/QA) is necessary to ensure consistent and quality bituminous road construction in India. It controls and assures that the material, process, and resultant output is all in compliance of the laid quality norms and guidelines and will prevent premature failures, create and deliver durable national assets.

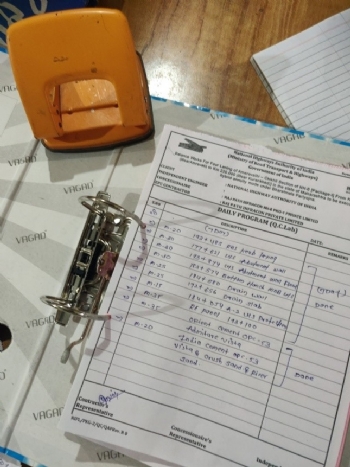

It is but natural to have doubts about the quality and the durability of the road that will be constructed with speed. However these queries can be put to rest if quality systems and norms are stringently employed and abided to, as done by Rajpath Infracon. The contractual requirement of the NHAI mandates maintenance of this road for 15 years. We at Rajpath consider it prudent to ‘Do It Right First Time’. This calls for strict quality control of the raw material used, monitoring the process of mixing, random batch sampling and testing and recording of the same.

Transporting bulk specimens from a remote site to a laboratory in the city is costly, time-consuming, and risks loss of the materials or damage to specimens. In order to overcome this obstacle and implement quality related testing, a full-fledged, well equipped in-house laboratory is necessary. Field labs are generally limited to a few particular important tests, but no matter the material, most require the same essentials to measure properties like size, weight, and moisture, which essentially decide the quality of the constructed road.

1. Make a decision on acceptance of quality produced,

2. Ensure that the Product is being consistently evaluated according to a given guideline of standards, and

3. Conforms without anomalies, to the level of as specified by the contract owner.

Quality Control is essential and is taken care by Rajpath Infracon’s system in place, during the construction of the road to manage, control and document our activities in order to comply with contract requirements.

We believe,

QC + QA = High Quality Finished Road constructed by Rajpath Infracon